Greater Anglia testing train cleanliness to boost effectiveness of sanitisation

October 16, 2020

Greater Anglia is now routinely using new testing equipment to make sure trains are cleaned as effectively and efficiently as possible.

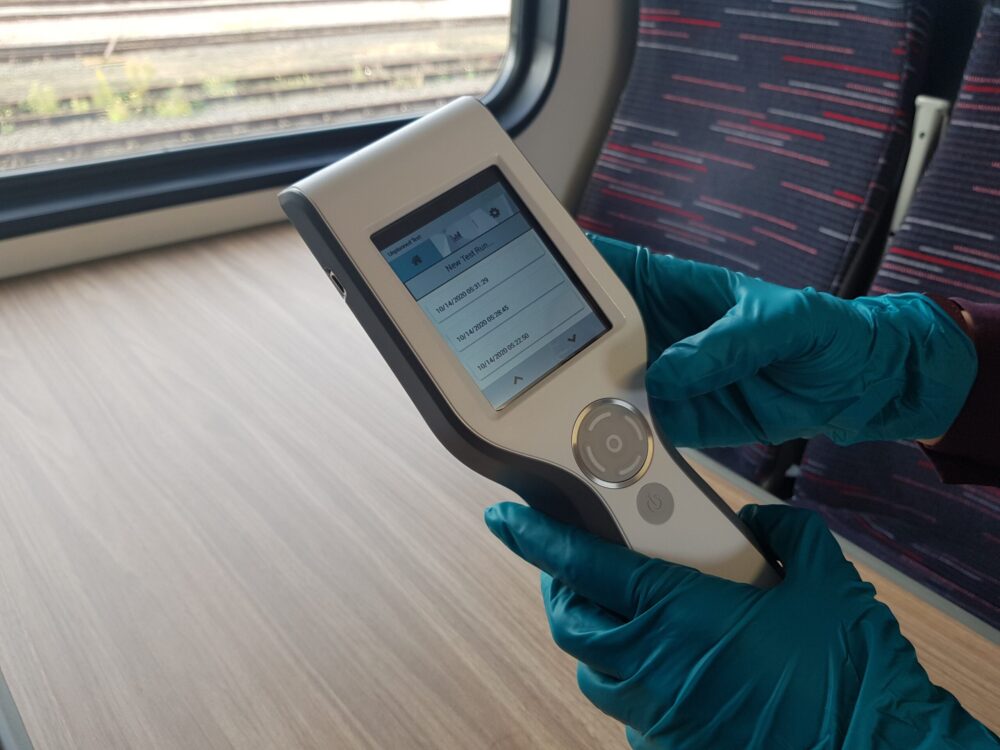

The company has five 3M hygiene monitoring units which are used weekly to quickly detect biological residue on high touch areas on board trains.

A swab is taken from the area being tested, which is checked for Adenosine Triphosphate (ATP), an indicator of biological residues.

The swab sample reacts with a lab-manufactured enzyme – replicating that found in fireflies called luciferase – in a self-contained device.

The energy from this reaction creates light. The more light detected, the greater the amount of biological residue on the surface tested.

Test results are then synchronised with one of Greater Anglia’s servers, so that train cleaning managers can get a picture of the efficiency and effectiveness of cleaning regimes across the whole of the network, enabling the company to provide optimal conditions for the sanitisation of trains.

This is the latest piece of equipment in an arsenal of cleaning and sanitising equipment Greater Anglia has introduced to keep trains as clean and sanitised as possible.

The company has spent £600,000 on new cleaning measures, including new equipment, extra cleaning routines, new and additional detergents and more staff.

New equipment includes seven fogging guns used to spray a fine targeted mist of anti-viral disinfectant which quickly kill off bacteria and viruses in the air, on floors, furniture, walls, ceilings, other surfaces and large internal areas.

Every single carriage on all of Greater Anglia’s trains had been fogged by the beginning of September, and the company is now doing them again.

Fogging guns are also being used by Greater Anglia’s cleaning contractors to sanitise waiting rooms, toilets and other areas at stations.

Greater Anglia also has eight Pacvac powerful backpack vacuum cleaners, fitted with four filters which clean the air as well as the floor and upholstery – especially useful for “turnaround cleaning” of trains at stations between arriving on one service and departing again on the next one.

Peter Tyler, Greater Anglia head of train presentation, said: “We’re doing everything we possibly can to keep our trains as clean and sanitised as possible.

“This new testing equipment enables us to check that our cleaning is as effective as possible, so that our customers can travel with us, confident that they are being kept safe.

“Our cleaning teams have been doing a great job and have really stepped up to the mark to keep everyone safe.

“Other staff, including our catering and station teams, have also stepped in to carry out additional cleaning on high touch areas such as ticket barriers and ticket machine touch screens.”